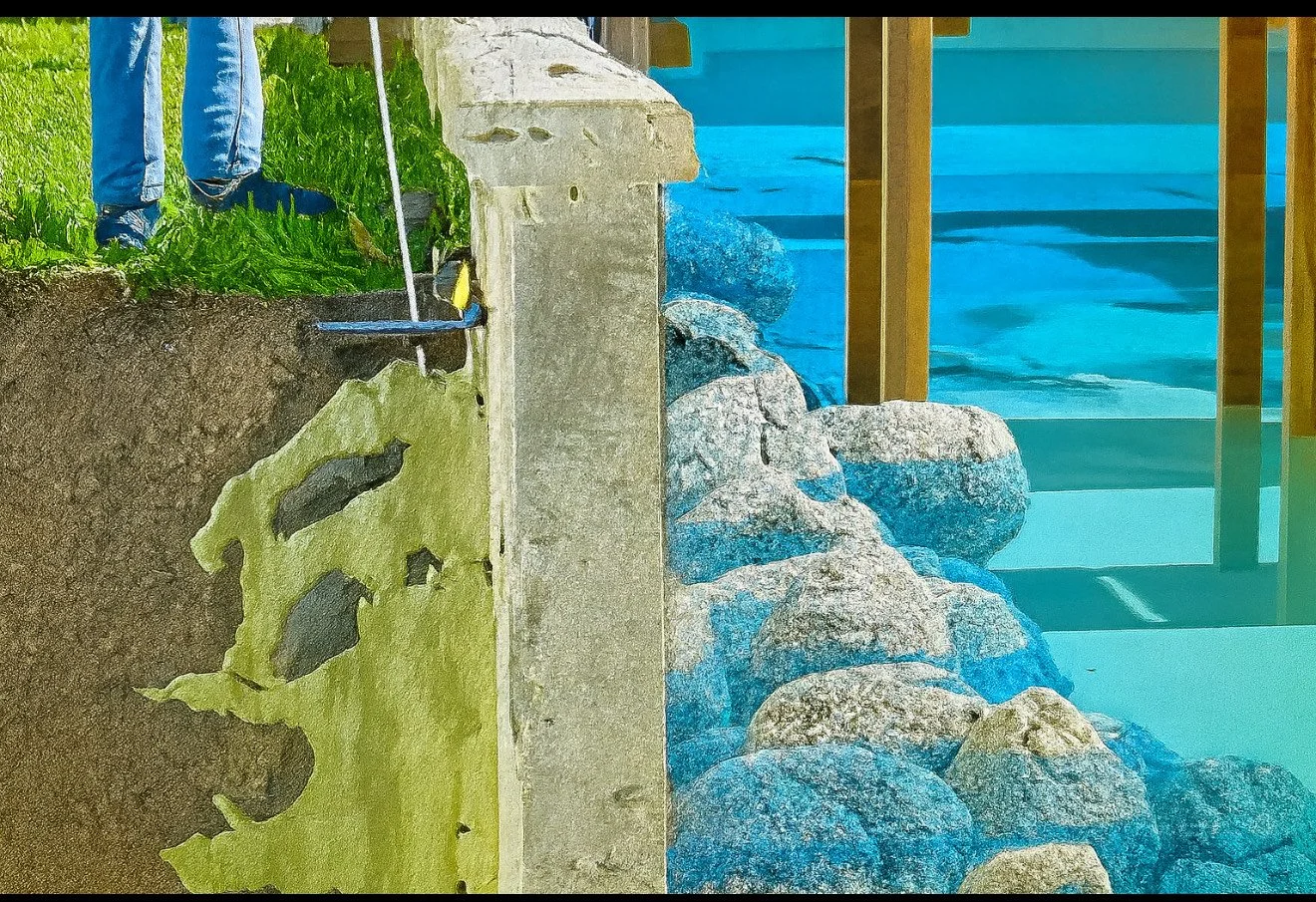

Seawall Repair Doesn’t Have to Be a Struggle Trust the Experts

Southshore Marine Construction Specializes In

🔧 Restoring compromised seawalls

🌬️ Repairing voids caused by erosion or settling

🌱 Addressing soil loss behind seawalls

🪨 Fixing structural cracks and joint separation

🚫 Providing solutions without full seawall replacement

How Seawall Foam Repair Works

Polyurethane Injection is a fast, effective, and minimally invasive solution that:

Stabilizes loose or eroding soils

Fills hidden voids behind seawalls

Seals cracks and separated joints

Prevents future erosion and structural damage

💡 Unlike other foam systems, our polyurethane:

🧪 Penetrates as a liquid, then expands to stabilize

⚖️ Is lightweight, reducing pressure on the seawall

🪨 Forms a soil composite, locking soil into a solid matrix

🧯 Prevents blowouts, thanks to low compressive stress

Polyurethane Injection – Step-by-Step Process

Site Assessment

We locate weak soil zones using inspection tools and mark injection sites.Targeted Injection

Rods are inserted at weak points to inject foam from bottom-up, ensuring full soil saturation.Rapid Curing

The foam cures fast, forming a stable, water-resistant composite that strengthens the foundation.

Key Benefits of Polyurethane Grout Injection

🛡️ Enhanced Resilience

Strengthens soil and prevents future seawall erosion.🚫 Minimal Disruption

No heavy equipment, no excavation, and no downtime for you.💸 Cost-Effective

Far more affordable than traditional replacement methods.🔄 Versatile Application

Perfect for seawalls, bulkheads, and other coastal structures.